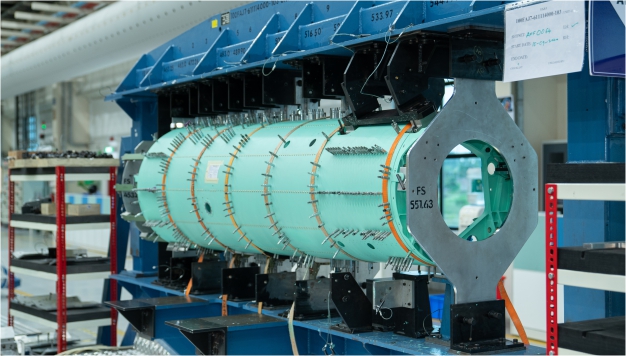

MACHINING

Our facilities are equipped with next-generation equipment for building critical and complex components such as high pressure turbines, compressor casings and compressor extension case.We also manufacture Structural components such as Forward Inner Nozzle Support. Our capabilities in design and manufacturing of complex machining fixtures assist in catering to high rate, high volume global supply chain demands powering major aircraft platforms. Our array of machines include 3-axis & 5-axis Mill Turn Center and Vertical Turret Lathe, which transforms titanium, steel and other hard & soft metals.

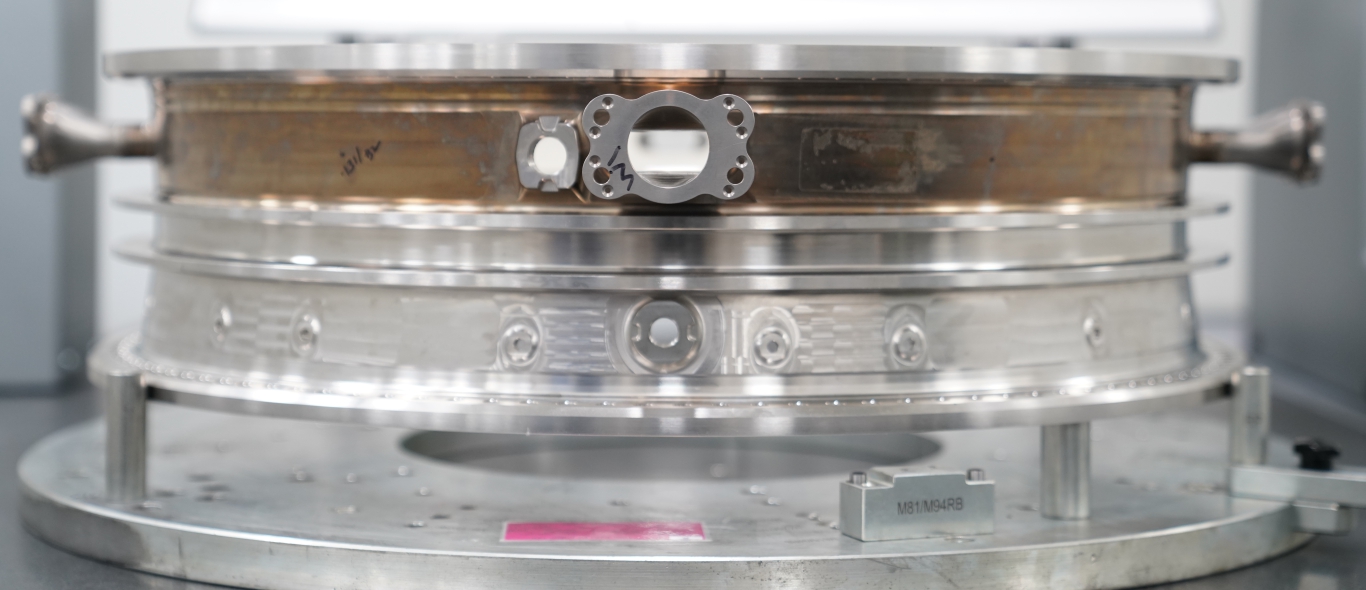

FABRICATION

We successfully manufacture detail parts like honeycomb stationary seals, rotary seals, heat shields and bearing housings. Our technical specialists are consistently upskilled to work on most advanced equipment for radiography, spectrometry, spark erosion grinding and electro discharge machining. The technology-assisted lean value chain for precision engine component manufacturing present under a single roof pushes our production rate.

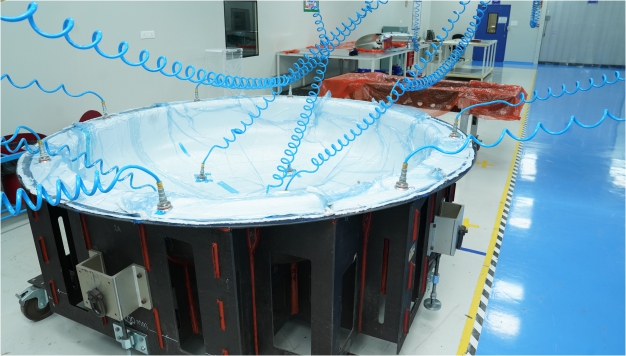

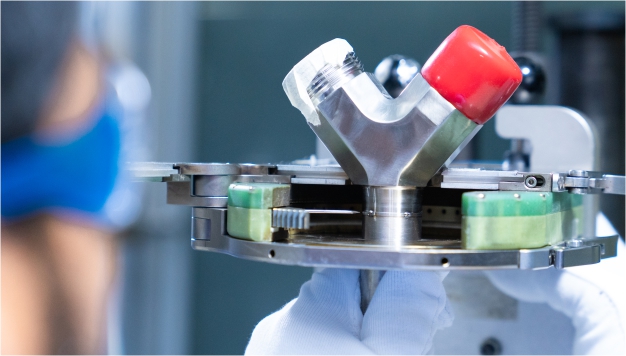

RIGID PIPES AND ASSEMBLIES

The variety of tools at our tube processing shop have been stationed to cover the wide range of capabilities and capacities demanded by the industry. Our capabilities encompasses Tube forming, multi-bend and assembly of Rigid Pipes for the fueling system of prevalent aero-engines. These processes are complemented with state-of-the-art equipment for tube cutting, tube bending & measurement, finishing, swaging and flushing on soft and hard metals.

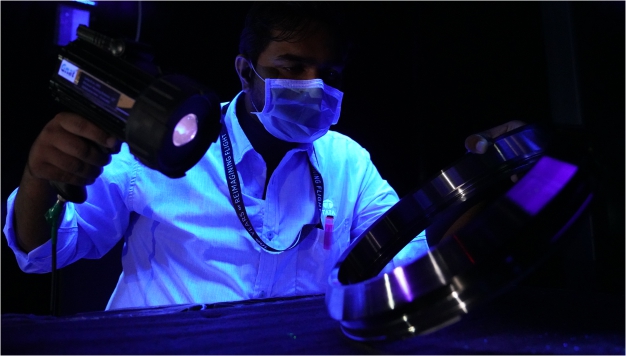

SPECIAL PROCESSES AND SURFACE TREATMENTS

Our aero-engine manufacturing capabilities include best-in-class special processes that are qualified by Nadcap, OEMs and Tier-1s. In order to control the end-to-end value chain, we have invested in all key processes that enable us to go from stock to finished product in-house. These special processes include but are not limited to Vacuum Heat Treatment and vacuum brazing. We perform surface treatments like Robotic Sacrificial coating, plasma and HVOF coatings. Our welding capabilities range through orbital, TIG, Spot and Electron beam welding.